Usually I was fixing rock nicks from the tubes, but a couple instances I ended up re-soldering the higher address with a rad. The price of purchasing and driving affordable beater automobiles as A child, eh, was that I experienced to master a handful of competencies to keep them operating.

We also use third-get together cookies that aid us review and understand how you employ this Site. These cookies will be saved inside your browser only with all your consent. You even have the option to opt-out of such cookies. But opting from Some cookies may possibly impact your searching knowledge.

Solder can be a successful choice In relation to restoring a radiator. In this post, we will think about the advantages and disadvantages of utilizing solder in radiator repair service and supply some tips for productive soldering.

Cleanse the aluminum by using a chrome steel brush. Aluminum types aluminum oxide promptly on contact with air, which slender layer of oxide can not be joined.[four] X Exploration supply

Soon after heating the leaky region in the radiator, gradually insert the wire into it. To prevent leaking afterward, make sure to entirely fill any cracks or flaws with ample solder.

Very low coolant can develop an air pocket or bubble in the cooling technique resulting in overheating and extreme damage. Generally be aware of what your gauges are Related Site demonstrating you and Look at your cooling program and fluid levels normally.

Utilize a soldering iron or a soldering iron stand using a developed-in scraper to clean out the solder and make an even surface area. Be careful not to apply far too much force, as this could problems the radiator.

Using these steps in mind, you have to be capable of efficiently entire this project without any challenges! Excellent luck!

When selecting solder to implement on aluminum, you need to often choose an acid-Main fluxed solder which contains no zinc. The acid inside the core may help clear the surface area of the metallic ahead of soldering starts.

You should definitely warmth the radiator until your solder begins to soften, which must only acquire a few minutes. Take into account that you require good air flow and eye safety when soldering.

Normally Enabled Necessary cookies are absolutely important for the website to operate effectively. These cookies make certain essential functionalities and safety features of the website, anonymously.

If you do not have to have an immediate take care of, nevertheless, there are many far more complex choices accessible as well which could go well with specific requirements much better based on their existing situation.

Before you start off soldering the radiator, Guantee that you do have a significant wattage soldering iron and weighty gauge, or very thick, soldering wire. Reduced wattage soldering irons will never make the warmth necessary to adequately melt the soldering wire as well as the radiator together.

Aluminum solder wire: Opt for a substantial-quality aluminum official source solder wire using a lower melting issue for greater success.

Angus T. Jones Then & Now!

Angus T. Jones Then & Now! Anna Chlumsky Then & Now!

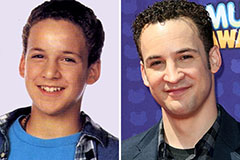

Anna Chlumsky Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Jennifer Love Hewitt Then & Now!

Jennifer Love Hewitt Then & Now! Christy Canyon Then & Now!

Christy Canyon Then & Now!